.jpg)

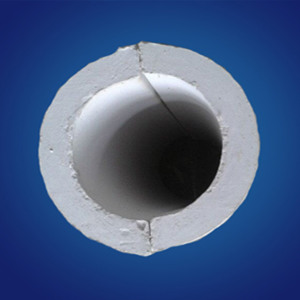

Nano Insulation Board is a new product manufactured by using special inorganic refractory nano powder and applying the latest nano technology. At high temperatures, its thermal insulation performance is more effective than traditional thermal insulation materials.

The product forms are plate and brick, and can provide outer protective layer materials such as PE heat shrinkable film and aluminum foil. The nano heat insulation material is environmentally friendly, the powder and reinforcing fibers in it meet the environmental protection standards, and will not cause harm due to being inhaled into the human body. It is an environmentally friendly material that is non-toxic to the human body.

2. Skill benefits are obvious. Minimize the heat dissipation of equipment, reduce the energy consumption of thermal kilns, and improve the production efficiency of kilns.

3. Satisfies high standard design requirements and has high cost performance.

4. It is not easy to pulverize at high temperature and has good durability. The thermal insulation performance is not attenuated, and it has better high temperature strength.

5. It is safe and hygienic to use. Does not contain toxic substances such as asbestos, sulfur, chlorine, etc., and is environmentally friendly.

|

Items |

JDN-1 Nano Insulation Board |

|

|

Color |

Grey |

|

|

Melting Point |

>1200℃ |

|

|

Maximum Operating Temperature |

1000℃ |

|

|

Bulk Density |

600kg/m³±10% |

|

|

Linear Shrinkage(900℃*3h) |

≤-1% |

|

|

Thermal Conductivity |

600℃ |

≤0.052W/m.k |

|

1000℃ |

≤0.085W/m.k |

|

|

Items |

JDN-II Nano Insulation Board |

|

|

Color |

Grey |

|

|

Melting Point |

>1200℃ |

|

|

Maximum Operating Temperature |

1000℃ |

|

|

Bulk Density |

600kg/m³±10% |

|

|

Linear Shrinkage(900℃*3h) |

<-1% |

|

|

Thermal Conductivity |

300℃ |

≤0.02W/m.k |

|

600℃ |

≤0.04W/m.k |

|

|

1000℃ |

≤0.065W/m.k |

|

|

Items |

JDN-H Nano Insulation Board |

|

|

Color |

White |

|

|

Classification Temperature |

1100℃ |

|

|

Melting Point |

>1200℃ |

|

|

Bulk Density |

300±10% kg/m³ |

|

|

Compressive Strength (compressed 10%) |

1.0Mpa |

|

|

Linear Shrinkage(900℃*3h) |

≤-1% |

|

|

Thermal Conductivity |

300℃ |

≤0.02W/m.k |

|

600℃ |

≤0.030W/m.k |

|

|

1000℃ |

≤0.038W/m.k |

|

JDN-I and JDN-II are suitable for medium and high temperature parts such as cyclone preheater, calciner, flue gas chamber, grate cooler, tertiary air duct, kiln hood, etc., and can partially replace traditional calcium silicate boards. JDN-H type is suitable for expansion of cement mill, calciner and preheater.